"We've tried a number of different types of materials for details and fixtures – Saturn's ceramic coating works the best by far"

Success Story: ITW Industrial Finishing -Buffing Fixtures

- Buffing operations utilize fixtures that are subject to severe abrasive wear to hold parts and mask non-buffed areas.

- ITW previously used solid ceramic fixtures or a combination of steel with solid ceramic or carbide in wear areas in the manufacturing and buffing of their industrial spray guns.

- In 1992, ITW began utilizing a cold rolled steel fixture with Saturn's ceramic coating in wear areas. These fixtures:

- Substantially outlasted uncoated steel or heat treated tools.

- Provide longer life and better machinablity than solid ceramic or carbide.

- Plus our Saturn Ceramic coated fixtures can be repaired & recoated.

- After over a decade of use, Saturn has continually proven to be the most cost effective method.

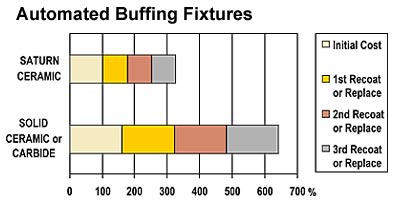

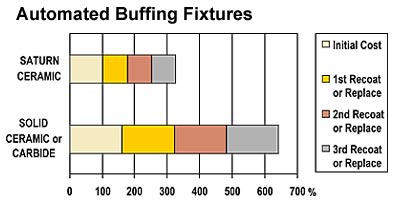

Saturn Ceramic: Lower initial cost, ability to recoat means substantial savings

- Based on fixtures with Solid Ceramic or Carbide costing 60% more than Saturn Ceramic coated fixtures. All have approximately equal life spans.

- Saturn Ceramic fixtures can be recoated for less than 50% of the cost toreplace Solid Ceramic or Carbide fixtures